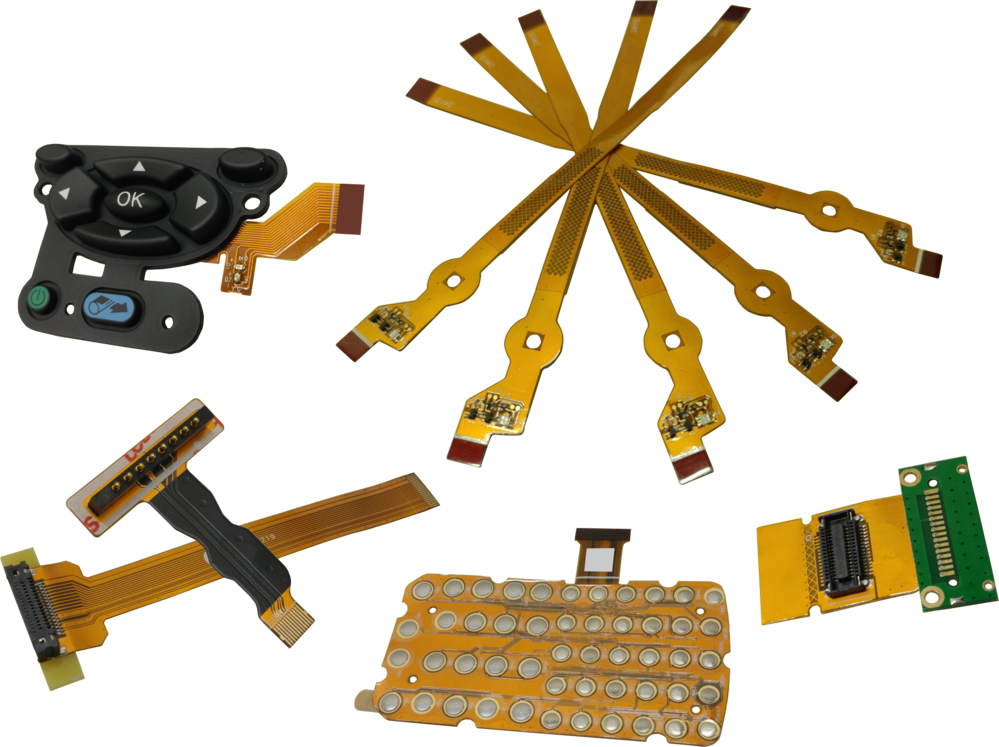

FPC with components

|

Base material |

PI (Polyimide) |

|

Thickness of base copper |

18µm/35µm (standard thickness) |

|

Largest size |

Single Sided-550mmx250mm Double Sided-500mmx250mm |

|

Min. hole diameter of drilling |

ø0.15mm/ 6mil |

|

Min. hole diameter of punching |

ø0.5mm/ 20mil |

|

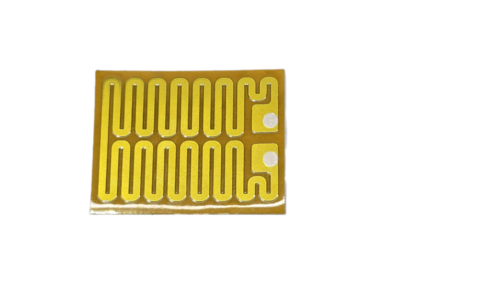

Min. Trace width / Min. Space |

0.075mm (3mil) |

|

Peeling strength |

1.0kg.f /cm |

|

Multi-layers |

Up to 4 layers |

|

Passive Component |

Min. 0201 |

|

Connector |

Min. Pitch0.3mm |

|

Stiffener |

PI (Polyimide), PET (Polyester), FR4, Metal |

|

Solder heat Temp |

PI (Polyimide) :250°C / 10sec |

|

Surface Treatment |

Gold plating:Ni:1um~4um + Au:0.05um~0.1um Immersion Gold:Ni:1um~4um ; Au:0.03um~0.09um OSP Immersion Tin:2µ" ~ 40µ" Tin Plating:200µ"~1000µ" |

|

Dimension Tolerances |

Conductor Width:±0.03mm~±0.05mm Outline Dimension:±0.1mm~±0.3mm Apply Coverlay Tolerance:±0.3~0.5mm Hole Diameter:±0.1mm |

|

Finish products testing |

ICT (In Circuit Test): proceed testing for SMT components to make sure the components locations are correct.

FCT (Function Test): proceed testing after SMT, but need customer provide us the fixture or machine. |